Product code: N/A

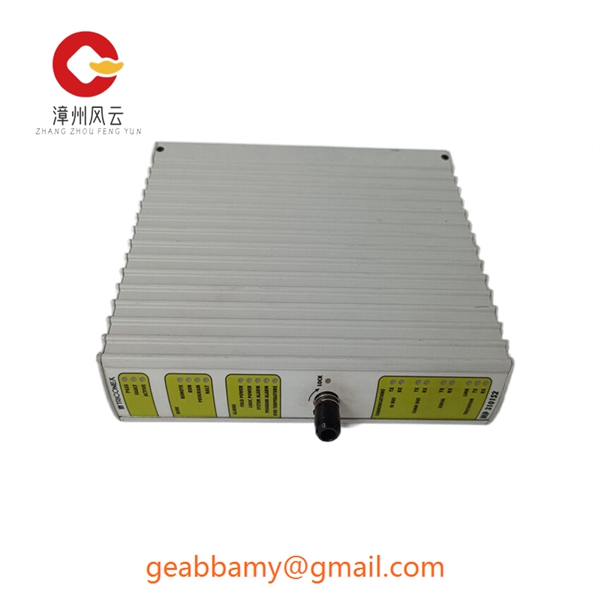

TRICONEX DI3301S2 Virtual Networked Device Sensors

📣Model Number:DI3301S2

🌍Country of origin: USA France Germany Estonia Norway UK

⌚Delivery date: in stock

🛠After-sales service: brand new with one year warranty

⚙️ Product Category: Module/Controller/Server/Motor/Touch Screen

🕰Warranty: 12 months/365 days

☎️ Please contact me: 15359029662 Ms. Amy Sun

📎Chinese official website: www.dcsplcabb.com

📩Email: geabbamy@gmail.com

💬Whatsapp: +86 15359029662

Detailed content

DI3301S2

The DI3301S2 can continuously monitor production operations, detecting anomalies based on its derived understanding. For example, the module can help operators detect deviations in the performance of equipment, such as mixers, that could affect product quality or cause downtime. It can also be used as a virtual sensor. Instead of workers taking readings such as humidity of packaged food, the module can analyse variables from line assets such as sprayers, dryers and burners to virtually predict measurements. Workers can then be notified of problems by configuring alerts on the human machine interface (HMI) or dashboard. The receive/transmit application is custom designed to meet the exact needs of the application. This includes the ability to allow manual control or include automated receive and transmit steps within the facility. Fully automated receiving/transferring applications track and transfer incoming materials to the correct location, such as grains and other commodity materials in feed manufacturing plants.

![]()

The DI3301S2 allows automation users to protect intellectual property throughout the enterprise automation layer by managing program changes using AutoSave. The latest version of AutoSave includes a new AutoSave client interface that extends this protection to non-networked devices, enabling users to make program changes in the field, and then analyse and synchronise all the changes when they return to the office. to the server. Included:

Version control for equipment programmes in remote locations

Tracking changes to non-networked equipment in the plant

Enables system integrators and off-site development teams to develop programs without direct access to equipment

Viewing a history of changes performed on each device

Compare programs running in equipment with programs on engineers’ laptops

Copy programs to create new programs in the field

_副本.jpg)

_副本.jpg)