Product code: N/A

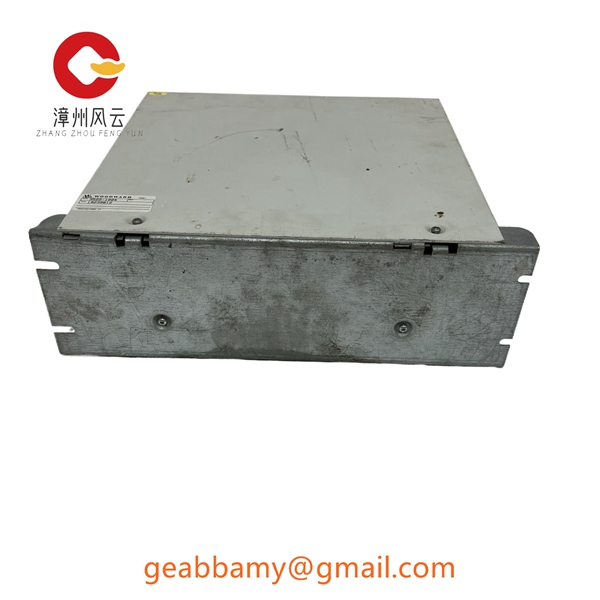

SHINKAWA VM-5N SST-2194-001-P001G Discrete Industrial Networks

📣Model Number: VM-5N SST-2194-001-P001G

🌍Country of origin: USA France Germany Estonia Norway UK

⌚Delivery date: in stock

🛠After-sales service: brand new with one year warranty

⚙️ Product Category: Module/Controller/Server/Motor/Touch Screen

🕰Warranty: 12 months/365 days

📦Product Packaging: seller provides complete and safe protection packaging

🚚 Freight: according to the local freight forwarder, the freight should be subject to different areas.

🆓Whether tariffs are included: no taxes are included

☎️ Please contact me: 15359029662 Ms. Amy Sun

📎Chinese official website: www.dcsplcabb.com

📩Email: geabbamy@gmail.com

💬Whatsapp: +86 15359029662

Detailed content

VM-5N SST-2194-001-P001G

VM-5N SST-2194-001-P001G The idea of using a PLC-based system rather than a distributed control system (DCS) has become a philosophical and technical debate in the industry. Distributed Control Systems (DCS) have always been the primary solution for process automation, but many PLC vendors are now pushing these applications, believing that a single integrated architecture based on PLCs and/or PACs (Programmable Automation Controllers) is the best way to automate the entire plant. In turn, DCS vendors are introducing PLC and PAC products. The primary logic for using a single PLC-based system rather than a DCS for process functions and a PLC for discrete functions is to provide a control architecture for the entire plant.

VM-5N SST-2194-001-P001G Connecting to Multiple Industrial Networks is Essential Almost all process plants utilize multiple discrete and process industry networks including DeviceNet, Profibus, Profinet, EtherNet/IP, Modbus TCP, HART, and Foundation Fieldbus DCS has a DCS has highly sophisticated and integrated interfaces to Foundation Fieldbus and HART as well as sufficient interfaces to other industrial automation networks.PLC systems often have less sophisticated interfaces to Foundation Fieldbus and HART. In many cases, they rely on third-party hardware and software and are more labor-intensive to configure. Oddly enough, discrete network interfaces can be a problem for PLC systems because there are many standards, and larger vendors optimize interfaces and software configurations for their flagship protocols, with weaker interfaces to competing protocols.