Product code: N/A

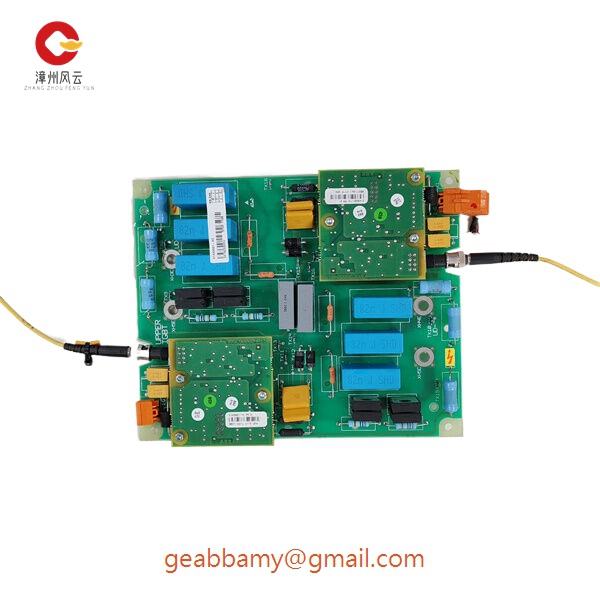

PM866A-2 3BSE081230R1 Multi-Port Ethernet/IP Devices

📣Model Number:PM866A-2 3BSE081230R1

🌍Country of origin: USA France Germany Estonia Norway UK

⌚Delivery date: in stock

🛠After-sales service: brand new with one year warranty

⚙️ Product Category: Module/Controller/Server/Motor/Touch Screen

🕰Warranty: 12 months/365 days

☎️ Please contact me: 15359029662 Ms. Amy Sun

📎Chinese official website: www.dcsplcabb.com

📩Email: geabbamy@gmail.com

💬Whatsapp: +86 15359029662

Detailed content

PM866A-2 3BSE081230R1

The PM866A-2 3BSE081230R1 features wireless LAN (Wi-Fi) capabilities, referred to as wired+wireless hardware. PAC Project version 8.5 supports all of these new components, thus providing industrial wireless networking capabilities that offer users multiple benefits, such as the ability to deploy the hardware in remote areas, inaccessible areas, or in places where it is difficult or impossible to install network cabling. hardware. Control system designers can also use the new wired+wireless hardware to design and build systems with traditional Ethernet cabling, Wi-Fi, or any combination of the two, establishing a new level of network flexibility that is not possible using standard components from any other industrial automation vendor. Wireless networking capabilities also provide significant cost savings through reduced cabling.

PM866A-2 3BSE081230R1 With this rapid recovery most faults are undetectable to devices on the network and machines can usually continue to run without interruption. Keeping plant floor production up and running helps increase machine uptime and productivity. In addition to superior network recovery performance, DLR technology helps simplify network architecture while still providing the flexibility to connect and coexist with other network topologies. Multi-port Ethernet/IP devices equipped with DLR technology connect directly to neighboring nodes and form a ring topology at the end device.PM866A-2 3BSE081230R1 is an intuitive flowchart and scripted control programming software for developing control strategies to run on SNAP PAC controllers, and is well suited for sequential, batch, and process control

_副本.jpg)