Product code: N/A

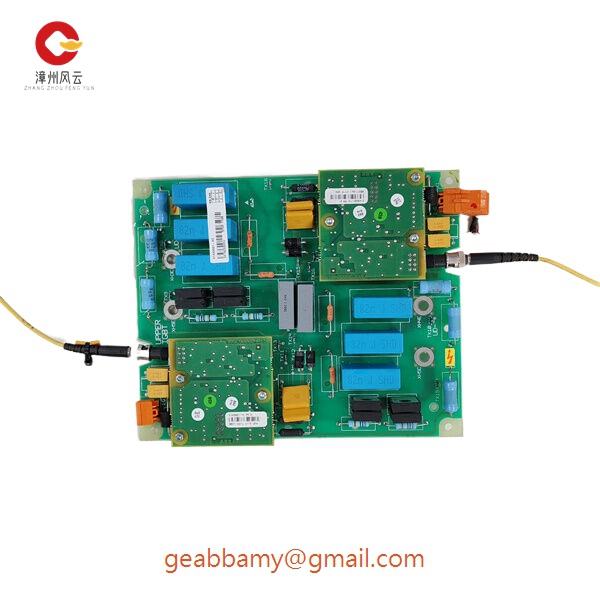

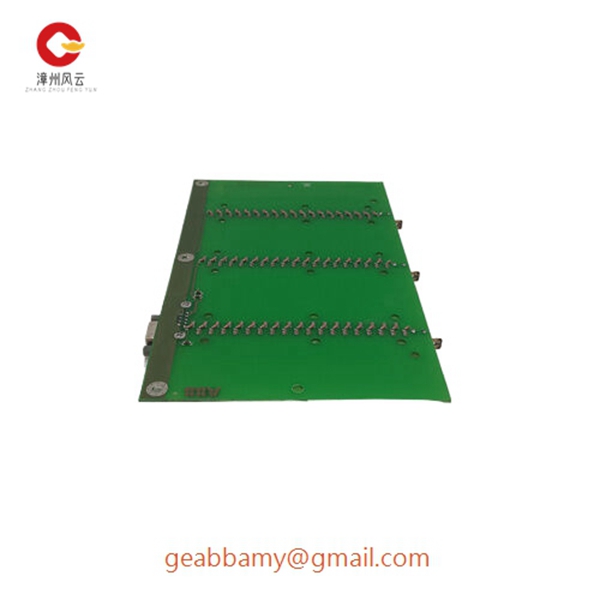

PFSK152 3BSE018877R1 Industrial Communication Converter

📣Model Number:PFSK152 3BSE018877R1

🌍Country of origin: USA France Germany Estonia Norway UK

⌚Delivery date: in stock

🛠After-sales service: brand new with one year warranty

⚙️ Product Category: Module/Controller/Server/Motor/Touch Screen

🕰Warranty: 12 months/365 days

☎️ Please contact me: 15359029662 Ms. Amy Sun

📎Chinese official website: www.dcsplcabb.com

📩Email: geabbamy@gmail.com

💬Whatsapp: +86 15359029662

Detailed content

PFSK152 3BSE018877R1

The basic premise of the PFSK152 3BSE018877R1 is that industrial applications can communicate with IT systems. However, operational technology (OT) on the factory floor uses fieldbus and industrial Ethernet networks that are designed for real-time communication – by default separate from the IT infrastructure. the Anybus .NET gateway solves this situation by acting as a converter that sends and receives data between a PROFIBUS or PROFINET network and an IT platform that uses .NET as a framework. NET as a framework. NET gateway is a very fast way to implement the IIoT as communication can be established in just a few minutes. NET gateway is a very fast way to implement IIoT. It automatically exports production and performance data for reporting and updating inventory. Second, importing master production schedules into individual machine job queues provides dynamic production scheduling and real-time job completion tracking.

NET gateway enables the IT side to make sense of data in addition to connecting data from industrial processes to IT systems. The exchange of information between the Operations Technology (OT) side and the Information Technology (IT) side is defined in a spreadsheet template that defines how the data is mapped, labelled and presented to the IT application. The spreadsheets are uploaded to the HMS Code Generator, which automatically creates customised high-level C# APIs (events and Post methods) that can be easily integrated directly into . It also generates custom GSDML files for PLCs. Receives up to four electrical operating signals from the machine. It records cycle times and rates, part and scrap counts, downtime, and calculates the machine’s Overall Equipment Effectiveness (OEE). Data is transmitted via wired or wireless Ethernet to support Production Manager or Job Manager software.