Product code: N/A

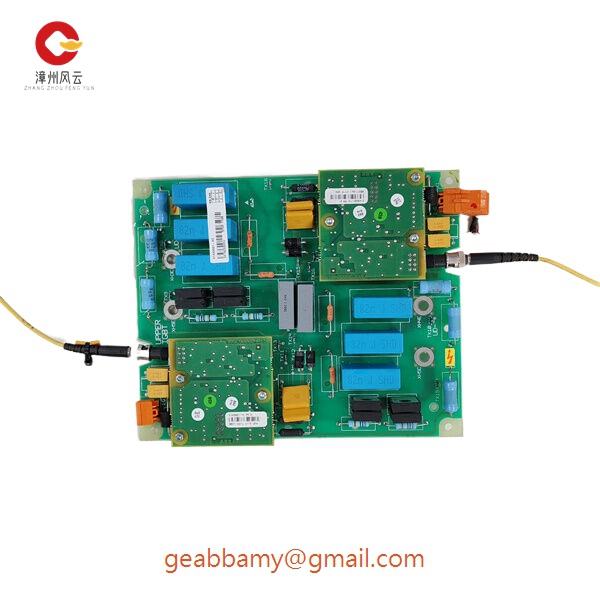

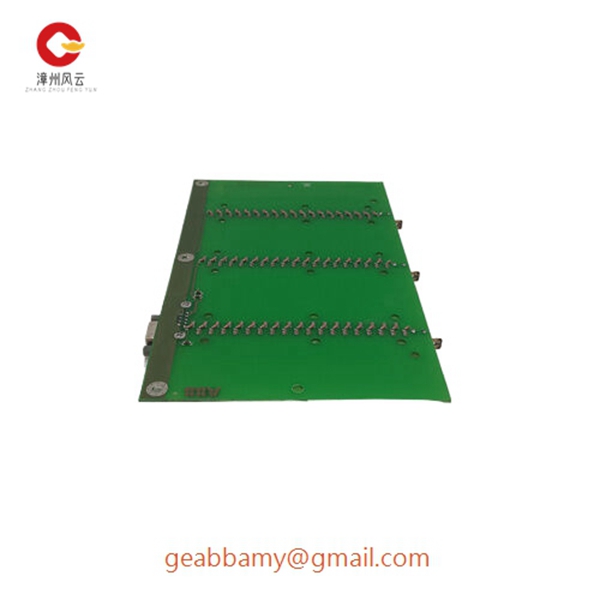

PDD205A1121 3BHE025335R1121 Monitoring Sensor Units

📣Model Number:PDD205A1121 3BHE025335R1121

🌍Country of origin: USA France Germany Estonia Norway UK

⌚Delivery date: in stock

🛠After-sales service: brand new with one year warranty

⚙️ Product Category: Module/Controller/Server/Motor/Touch Screen

🕰Warranty: 12 months/365 days

☎️ Please contact me: 15359029662 Ms. Amy Sun

📎Chinese official website: www.dcsplcabb.com

📩Email: geabbamy@gmail.com

💬Whatsapp: +86 15359029662

Detailed content

PDD205A1121 3BHE025335R1121

PDD205A1121 3BHE025335R1121 is designed for process control and industrial automation applications.CIP provides consistent device access, allowing a single configuration tool to monitor and configure CIP devices without the need for vendor-specific software.Red Lion’s rugged NT24k and 700/7000 managed switches provide information and configuration access directly to human machine interfaces (HMIs) and programmable logic controllers (PLCs) through standard CIP The Red Lion ruggedised NT24k and 700/7000 managed switches provide information and configuration access directly to Human Machine Interfaces (HMIs) and Programmable Logic Controllers (PLCs) through standard CIP messaging. Permanently attached, two-wire, individually shielded cables are completely encased in polyurethane. The sensor has a sensitivity of 100mV/g, a resolution of 0.001g, and a frequency range of 5,000 to 50,000Hz for measuring energy spikes.

PDD205A1121 3BHE025335R1121 provides users with direct feedback and communication with the equipment control system, automatic lubrication when necessary, and automatic maintenance. Manual lubrication is no longer required and lubricant usage can be reduced by up to 30%. Automatic condition monitoring provides predictive maintenance, which improves availability and quality and reduces total cost of ownership. When linear roller bearing and guideway assemblies are used in the delivery condition or in feed spindles, the operating characteristics of the guideways and the condition of the lubricant are usually at their optimum. This can be seen by the vibration behaviour of the saddle plate when the system is in motion. In order to determine variations and deviations from the ideal nominal values, piezoelectric accelerometers are mounted on the steel saddle plates on the guideway brackets. The accelerometers are suitable for use in coolant and harsh contaminated environments.

_副本.jpg)