Product code: N/A

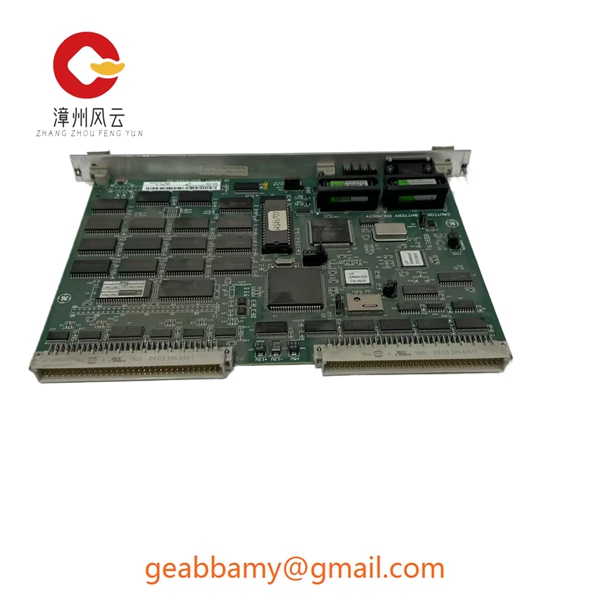

IS200TDBTH6ACD Virtual Machine Tool Service Components

📣Model Number:IS200TDBTH6ACD

🌍Country of origin: USA France Germany Estonia Norway UK

⌚Delivery date: in stock

🛠After-sales service: brand new with one year warranty

⚙️ Product Category: Module/Controller/Server/Motor/Touch Screen

🕰Warranty: 12 months/365 days

☎️ Please contact me: 15359029662 Ms. Amy Sun

📎Chinese official website: www.dcsplcabb.com

📩Email: geabbamy@gmail.com

💬Whatsapp: +86 15359029662

Detailed content

IS200TDBTH6ACD

IS200TDBTH6ACD With Intelligent Dynamic Control (IDC), it is possible to balance the dynamic and control parameters of the machine axes across the axes. Setting this function will optimize the parameters in the machine’s work area, resulting in a more accurate machine. the CNC Sinumerik 840-D sl will also support technical functions such as IDC and ILC. Activities such as running a new NC program can be transferred to the virtual world.NX Virtual Machine Tool Services supports machine builders and machine operators in creating digital twins. From engineering and implementation to training and support services, GE covers the entire lifecycle of the machine tool digital twin.

The IS200TDBTH6ACD Common Component creates a library of routines to simplify the development of FDT/FRAME-compatible applications to provide an open, integrated, single access point to the network and installed assets. Original Equipment Manufacturers (OEMs) can use these tools to develop FDT/FRAME with company-specific branding by bundling FRAME applications with DTMs and distributing them to customers as a complete turnkey solution for device parameterization. In addition, generic components can be integrated with engineering applications such as Programmable Logic Controller (PLC) programming tools, Distributed Control Systems (DCS), asset management applications, or virtually any other type of software application.

-2_副本.jpg)