Product code: N/A

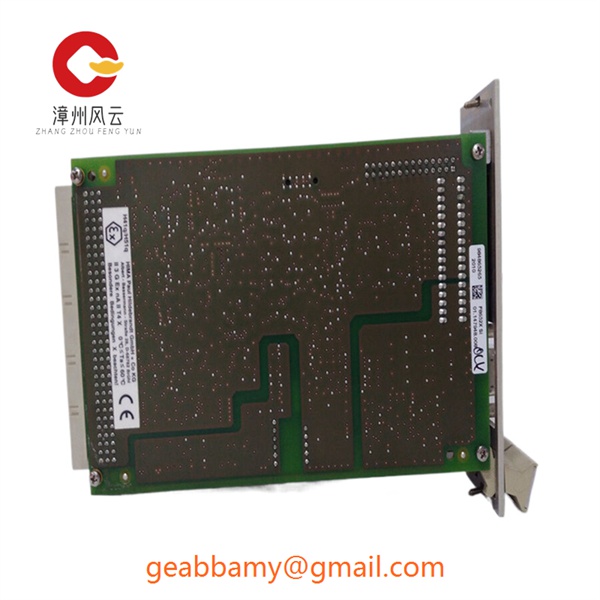

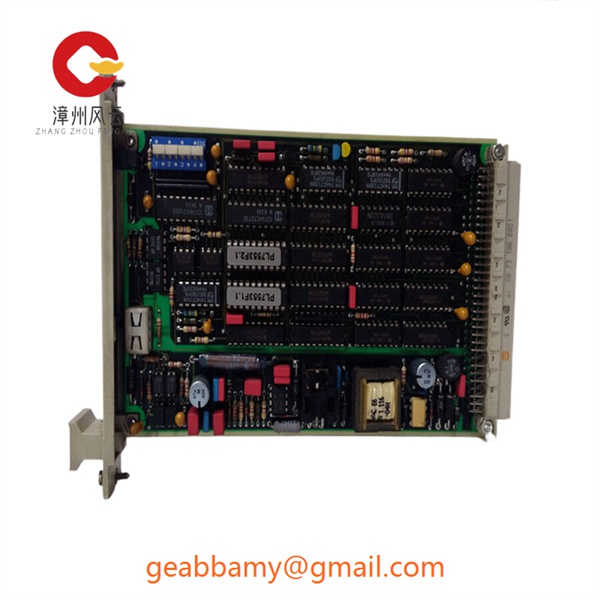

F3 DIO 88 01 New integrated control system

📣Model Number:F3 DIO 88 01

🌍Country of origin: USA France Germany Estonia Norway UK

⌚Delivery date: in stock

🛠After-sales service: brand new with one year warranty

⚙️ Product Category: Module/Controller/Server/Motor/Touch Screen

🕰Warranty: 12 months/365 days

☎️ Please contact me: 15359029662 Ms. Amy Sun

📎Chinese official website: www.dcsplcabb.com

📩Email: geabbamy@gmail.com

💬Whatsapp: +86 15359029662

Detailed content

F3 DIO 88 01

The F3 DIO 88 01 integrates CNC, PLC, operator panel and axis control for six CNC measuring circuits into a robust single operator panel. With intelligent motion transformation, an efficient tool management system and 80-bit floating-point nanometer accuracy, this new control system offers a range of performance features previously reserved for advanced CNC control.The Sinumerik 828D has fully graphical high-level language commands and also supports ISO programming, which is commonly used in Asia and the United States. Extensive online help animations and a new input prompting system with dynamic image sequences provide excellent user convenience. USB, compact flash (CF) cards and Ethernet ports support high-speed transfer of data to storage media or integration of the control system into corporate networks.

The F3 DIO 88 01 can be used with all types of CNC programming methods used worldwide. This offers machine builders the opportunity to sell their products worldwide with only one CNC machine option. the Sinumerik 828D is suitable for small one-piece series as well as large series production. Programming times for small series can be further reduced by using the ShopMill and ShopTurn graphical work step programming systems. For large series production, the combination of high-level language programming and programGuide allows parameterization of the technical cycle and thus significantly reduces programming times. Thanks to its Easy Message function, the F3 DIO 88 01 monitors the production status via text message (SMS). Depending on the recipient’s profile settings, the machine transmits information about the machining status of the workpiece, reports on the status of the tools currently in use, and sends a machine maintenance bulletin to the cell phone at any time and from anywhere. These combined functions help to minimize machine downtime.