Product code: N/A

D20 EME210BASE-T Redundant safety interlocks

📣Model Number:D20 EME210BASE-T

🌍Country of origin: USA France Germany Estonia Norway UK

⌚Delivery date: in stock

🛠After-sales service: brand new with one year warranty

⚙️ Product Category: Module/Controller/Server/Motor/Touch Screen

🕰Warranty: 12 months/365 days

☎️ Please contact me: 15359029662 Ms. Amy Sun

📎Chinese official website: www.dcsplcabb.com

📩Email: geabbamy@gmail.com

💬Whatsapp: +86 15359029662

Detailed content

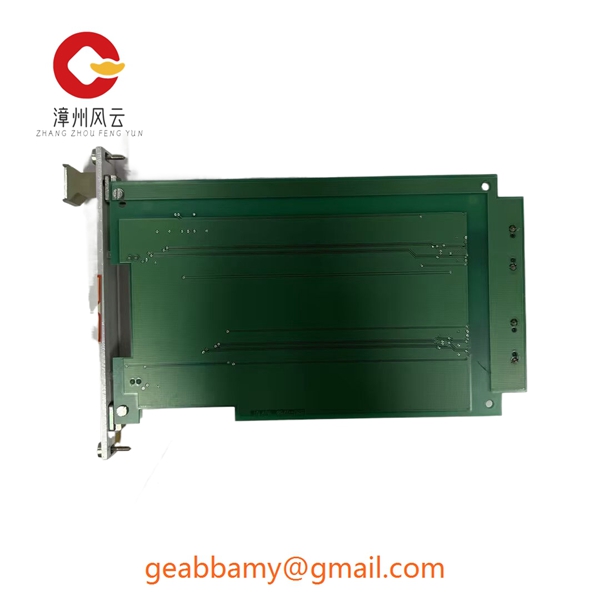

D20 EME210BASE-T

The D20 EME210BASE-T is suitable for applications such as drying, shrinking, preheating substrates, and de-flashing plastic parts. Malcom Hot Air process heating control systems include programmable PLCs that can be pre-configured for multiple zones, each with independently controlled heaters and/or blowers, and redundant safety interlocks. Designed for plug-and-play operation, these hot air process heating control systems include counters, timers, variable airflow rates, recipes, and more; pre-configured and fully tested for customer-specific applications. Designed to integrate with existing production and packaging applications, the Malcom Hot Air Process Heating Control System can accommodate a variety of heat sources and interface with customers’ other industrial controllers. Control cabinets can include LCD displays and switches or touch screens and are UL508A compliant. Systems can be built with up to 12 zones, up to 40 kW and 1000 CFM, 120-480 V, 1-phase or 3-phase electrical requirements.

The D20 EME210BASE-T achieves this by operating as both a Profibus-DP slave on a Profibus network and a CAN node on a J1939 network. Data is exchanged from either network according to a user-defined configuration. HMS provides a free Windows-based configuration tool (BWConfig) that allows the user to map J1939 parameter (PGN) data to the module’s Input and Output tables, which can be accessed by the Profibus master over the Profibus-DP network. With its rugged industrial design, the device is designed for a variety of applications and industries. These include use in agriculture, construction, fire and rescue, oil and gas, mining, power generation, motor control, material handling, trucking, mass transit and marine applications. Typical uses include applications in oil and gas production, or on-board applications where the gateway is used as an interface between the J1939 network and Profibus-based industrial PLCs. On the Profibus side, the gateway supports Profibus-DP slave functionality with cyclic I/O data transfer, handling up to 244 bytes of input and 244 bytes of output data.