Product code: N/A

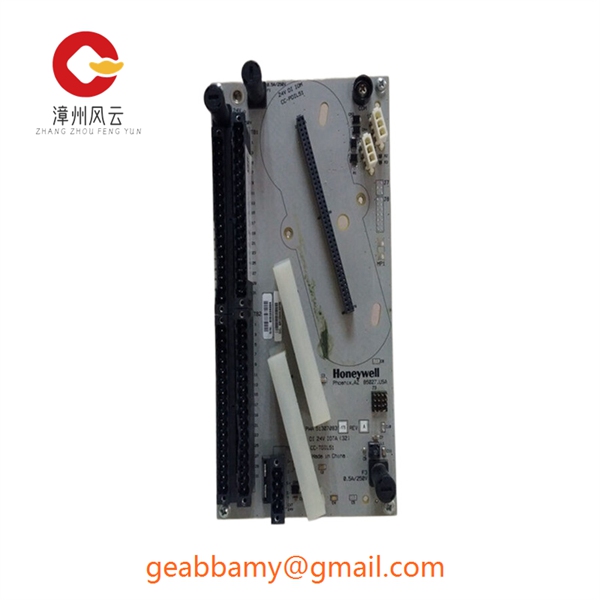

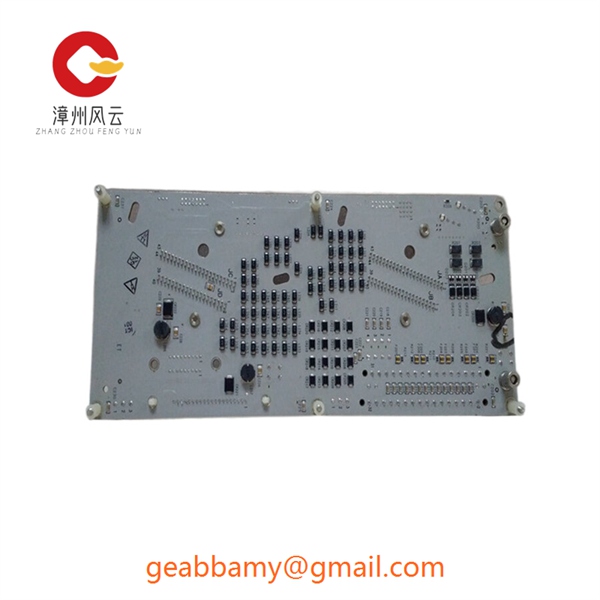

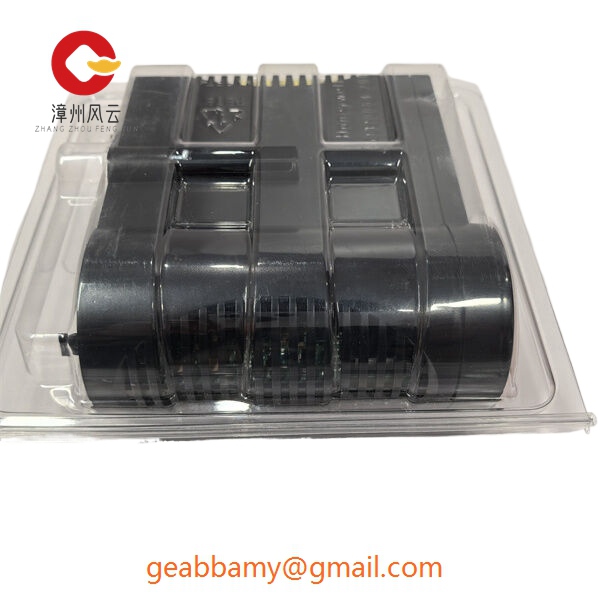

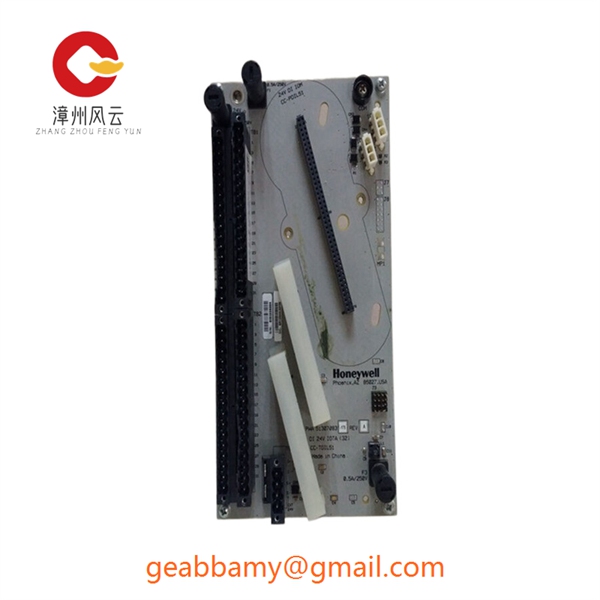

CC-TDIL51 51307083-175 High Speed Input/Output Modules

📣Model Number:CC-TDIL51 51307083-175

🌍Country of origin: USA France Germany Estonia Norway UK

⌚Delivery date: in stock

🛠After-sales service: brand new with one year warranty

⚙️ Product Category: Module/Controller/Server/Motor/Touch Screen

🕰Warranty: 12 months/365 days

☎️ Please contact me: 15359029662 Ms. Amy Sun

📎Chinese official website: www.dcsplcabb.com

📩Email: geabbamy@gmail.com

💬Whatsapp: +86 15359029662

Detailed content

CC-TDIL51 51307083-175

CC-TDIL51 51307083-175 provides customisable control of XC controllers for easy expansion with compact, high-speed input/output (I/O) modules. Up to 15 HIOC Local Expansion Modules can be directly connected to each controller and can be used in a variety of high density channel, analogue, temperature, counter and communication modules. In addition, the XC controller has eight digital inputs and six digital outputs as standard. Ethernet access provides efficient communication between the controller and the data exchanged to higher level control systems using communication standards including Object Linking and Embedding (OLE) for Process Control (OPC). The controller utilises the IEC 61131-3 compliant CODESY programming environment to support interoperability with multi-vendor equipment. The code set has a range of features for programming, testing and debugging that simplify and organise program documentation, diagnostics and debugging.

CC-TDIL51 51307083-175 automatically generates accurate synthetic documentation, which can be useful for reverse engineering, whether for new development based on legacy code or for maintenance and modernisation. Unfortunately, code is often the only documentation available, and working on an undocumented programme is always a waste of time. In addition, writing documentation manually is tiresome and error-prone. The need for a completely consistent format and the tedium of the work requires a tool-based automation approach. The module automatically generates a data-flow orientated view of the PLC program (from inputs to outputs) represented by formulas and flowcharts, thus abstracting the actual sequential execution of the program. This view is the perfect intermediate formalism between the specification and the code itself. It is independent of the programming style and type of PLC hardware on which the program runs. In addition, modules can be parameterised with any type of document template (title block, symbols…), thus ensuring consistent formatting of all documents.