You are here:

- Home

- Product

- BENTLY NEVADA

- BENTLY 3500/25 149369-01 Code Generator

Product code: N/A

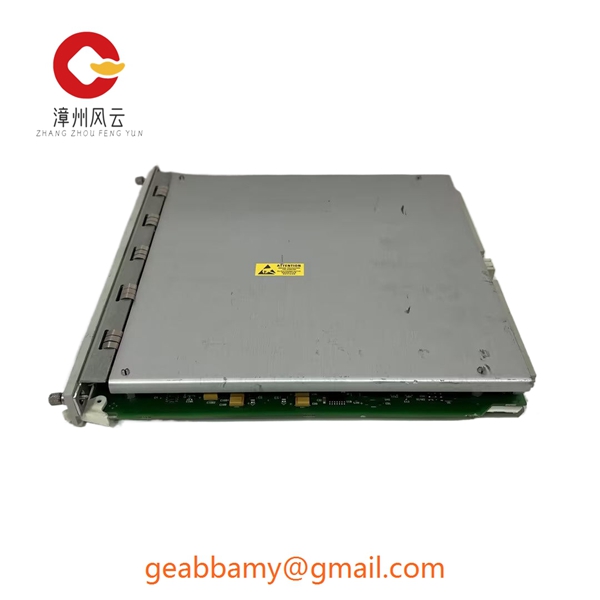

BENTLY 3500/25 149369-01 Code Generator

📣Model Number:BENTLY 3500/25 149369-01

🌍Country of origin: USA France Germany Estonia Norway UK

⌚Delivery date: in stock

🛠After-sales service: brand new with one year warranty

⚙️ Product Category: Module/Controller/Server/Motor/Touch Screen

🕰Warranty: 12 months/365 days

📦Product Packaging: seller provides complete and safe protection packaging

🚚 Freight: according to the local freight forwarder, the freight should be subject to different areas.

🆓Whether tariffs are included: no taxes are included

☎️ Please contact me: 15359029662 Ms. Amy Sun

📎Chinese official website: www.dcsplcabb.com

📩Email: geabbamy@gmail.com

💬Whatsapp: +86 15359029662

Detailed content

BENTLY 3500/25 149369-01

The BENTLY 3500/25 149369-01 software package enables manufacturers and machine builders to drastically reduce the overall cost of machine project development, commissioning time and ownership. The software can be downloaded via a web site, run as a custom application on the user’s machine and connected to a database hosted by the PLC Code Generator. Users simply configure their machine project, including all machine I/O (inputs and outputs), I/O relationships and general machine sequences. The software then produces a complete PLC program with full machine control (including automatic and manual forward/reverse modes) and diagnostic functions, as well as a complete set of program addresses and crossfile comments. Meet the growing demand for tightly integrated PLCs and motion controllers. In addition to precise single-axis positioning, the Technology CPU is particularly well suited to complex simultaneous motion applications, and allows users to combine standard EC-61131 PLC programming with open-compatible motion control functions into a high-performance unit that is fully integrated into Siemens’ fully integrated automation architecture.

The BENTLY 3500/25 149369-01 also includes programming and tag generation via commonly used touch screens or HMIs. emjen’s initial process review of the software included the application of the PLC Code Generator to generate PLC programs for at least 3 different machines with a total I/O count of approximately 150. As these machines had been previously programmed, emjen was able to provide a time and cost effective solution. Analysis of manually programmed machines versus generating programs using the PLC Code Generator. Results: average time savings of more than 80% and average cost savings of more than 50%. the CPU is designed for machines requiring high PLC performance and motion control functionality for the following applications: filling and packaging; converting and assembly; flying shears; carton assembly and labeling machines; etc. Integration of automation and motion control in a single SIMATIC CPU results in significant engineering and operational savings: filling and packaging; processing and assembly; flying shears; carton assembly and labeling machines; and more. Integration of automation and motion control in a single SIMATICCPU results in significant engineering and operational savings