You are here:

- Home

- Product

- EMERSON EPRO

- EPRO MMS6110 EMERSON Relative Rotor Vibration Monitor

Detailed content

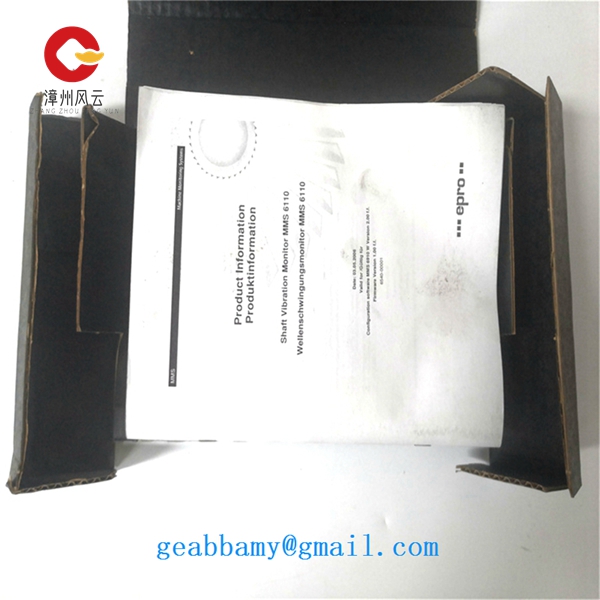

Note:All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication.

Technical Parameters of MMS6110 EMERSON Relative Rotor Vibration Monitor

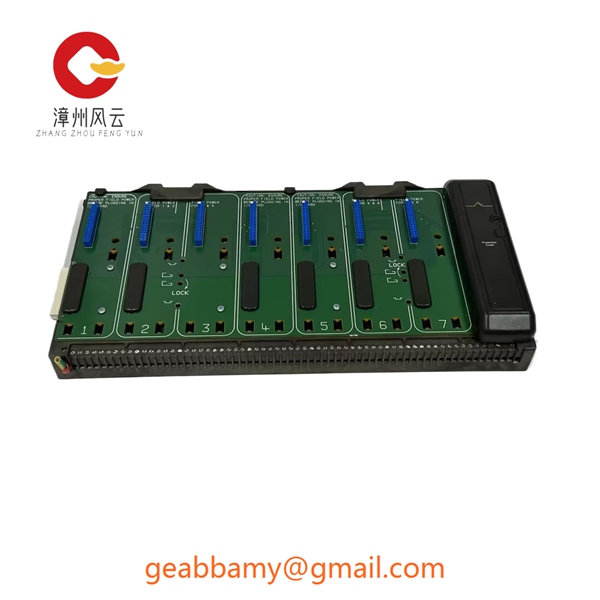

The MMS6110 is a dual-channel relative rotor vibration monitor manufactured by Emerson, designed for continuous monitoring of radial relative vibration in rotating machinery such as steam turbines, gas turbines, compressors, and fans. Below are its key technical specifications:

1. MMS6110 Core Functions

- Dual-Channel Configuration:

- Two independent measurement channels (SENS 1H/SENS 1L and SENS 2H/SENS 2L) support simultaneous monitoring of two axial positions.

- Each channel operates independently, enabling differential analysis or redundant protection.

- Sensor Compatibility:

- Designed for use with EPRO PR642X series eddy-current sensors and associated前置器 (CON0X1), with support for third-party sensors meeting similar specifications.

- Input voltage range: -1 V DC to -22 V DC for sensor excitation.

- Keyphasor Input:

- Dedicated keyphasor input (≥13 V DC) for phase reference, critical for vibration analysis and dynamic balancing.

2. MMS6110 Signal Processing & Outputs

- Analog Outputs:

- Current Output: Two configurable 0/4–20 mA or 4–20 mA outputs per channel (I1+/I1- and I2+/I2-), proportional to measured vibration.

- Voltage Output: Two 0–10 V DC outputs (EO1/EO2) for direct connection to control systems.

- Dynamic Signal Output: Two 0–20 Vpp AC outputs (AC1/AC2) for frequency spectrum analysis.

- Gap Voltage Output: Two 0–10 V DC outputs (NGL1/NGL2) proportional to sensor-to-target distance.

- Alarm & Trip Logic:

- Programmable alarm thresholds (Alert/Danger) per channel, with hysteresis adjustment (1–10% of full scale) to prevent nuisance trips.

- Limit Multiplier Function: During transient events (e.g., critical speed), alarm/trip thresholds can be dynamically scaled (1.00–5.00×) to avoid false alarms.

- Latching Alarms: Alarm states persist until reset via software command, ensuring operator awareness.

3. MMS6110 Communication & Configuration

- Interface:

- RS232/RS485 ports for local configuration and data retrieval.

- Modbus RTU/TCP (optional) for integration with DCS/PLC networks.

- Configuration Modes:

- Dual-Channel Mode: Independent setup of range, sensor type, and thresholds per channel.

- Smax Mode: Outputs the vector sum of two orthogonal vibration channels (X/Y) as a single value.

- Sppmax Mode: Outputs the peak-to-peak maximum of two channels.

- Data Logging:

- Stores the last startup/shutdown cycle’s vibration data for post-analysis.

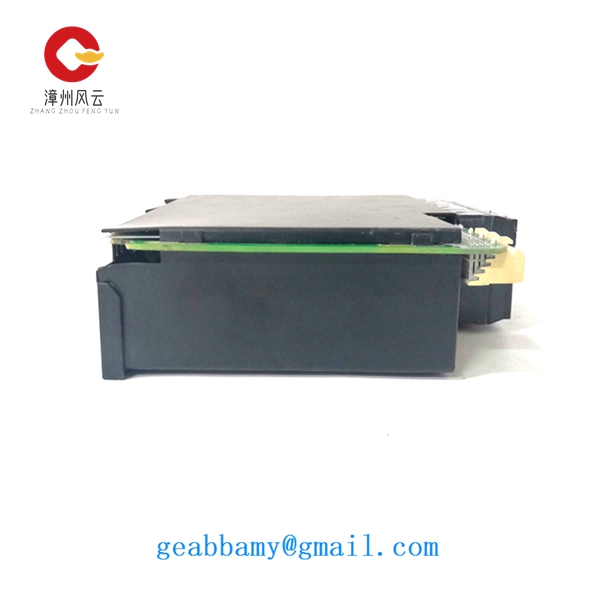

4. MMS6110 Mechanical & Environmental Specifications

- Dimensions: 150 mm × 150 mm × 40 mm (standard 19″ rack-mountable).

- Power Supply: Redundant 24 V DC inputs (18–30 V DC range).

- Operating Temperature: -20 °C to +60 °C (compliant with IEC 60068-2).

- Protection Class: IP20 (front panel), IP67 (with optional CON011 connector).

5. MMS6110 Diagnostics & Redundancy

- Self-Diagnostics:

- Continuous monitoring of sensor health (short-circuit/open-circuit detection).

- Overload detection for dynamic signals.

- Temperature monitoring with configurable alert/trip thresholds.

- Hot-Swappable Design: Allows module replacement during operation without power interruption.

For more products, click here

This article is from the official website of Zhangzhou FengYun, please include the following link for reproduction:www.fy-module.com |MMS6110

Related products:

PP881

PP881 3BSE092978R1

3BSE069274R1

PP877K

PP877K 3BSE069274R1

3BSE092977R1

PP875