Product code: N/A

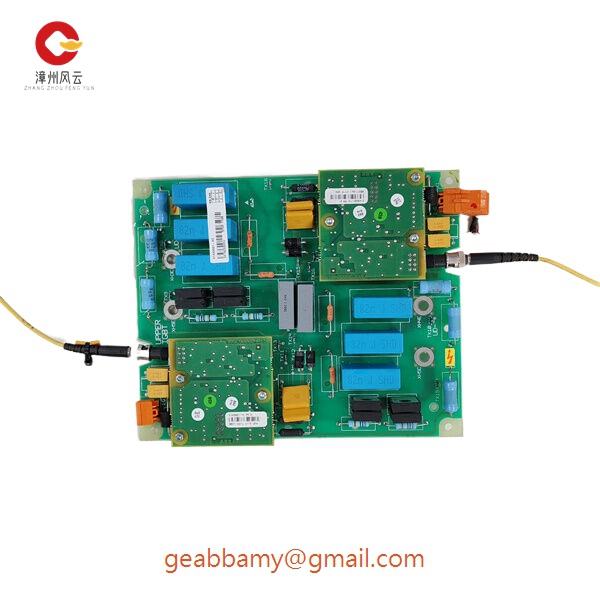

PDD200A101 3BHE019633R0101 Ethernet Integrated Architecture

📣Model Number:PDD200A101 3BHE019633R0101

🌍Country of origin: USA France Germany Estonia Norway UK

⌚Delivery date: in stock

🛠After-sales service: brand new with one year warranty

⚙️ Product Category: Module/Controller/Server/Motor/Touch Screen

🕰Warranty: 12 months/365 days

☎️ Please contact me: 15359029662 Ms. Amy Sun

📎Chinese official website: www.dcsplcabb.com

📩Email: geabbamy@gmail.com

💬Whatsapp: +86 15359029662

Detailed content

PDD200A101 3BHE019633R0101

With more than 100 ready-to-use motion systems for Delta, SCARA and Cartesian-type robots, the PDD200A101 3BHE019633R0101 controller provides a complete six-axis path planner and the ability to run multiple motion systems simultaneously. Features include up to 64 control axes, dynamic belt synchronization of multiple conveyors, and an integrated vision system interface. A motion wizard is available for easy configuration. It will provide alternate routing of data to help restore the network at very high speeds. Enhanced diagnostics built into DLR-enabled products identify points of failure, helping to speed maintenance and reduce mean time to repair.

The PDD200A101 3BHE019633R0101 provides a maximum response time of 18.7 milliseconds-probably less than 1/6th of the response time of competing secure I/O terminals. the typical response time for secure I/O terminals can be longer than for standalone systems because it depends on the network system architecture. Therefore, a fixed maximum response time is an important feature because it allows for quick and safe movement of the machine to a safe state, regardless of the network architecture, number of I/O modules, or overall program complexity. With this fast recovery, most faults are undetectable to devices on the network and machines can usually continue to operate without interruption. Keeping plant floor production up and running helps increase machine uptime and productivity.

_副本.jpg)