Product code: N/A

FBMSVH Automatic Overflow Protection System

📣Model Number:FBMSVH

🌍Country of origin: USA France Germany Estonia Norway UK

⌚Delivery date: in stock

🛠After-sales service: brand new with one year warranty

⚙️ Product Category: Module/Controller/Server/Motor/Touch Screen

🕰Warranty: 12 months/365 days

☎️ Please contact me: 15359029662 Ms. Amy Sun

📎Chinese official website: www.dcsplcabb.com

📩Email: geabbamy@gmail.com

💬Whatsapp: +86 15359029662

Detailed content

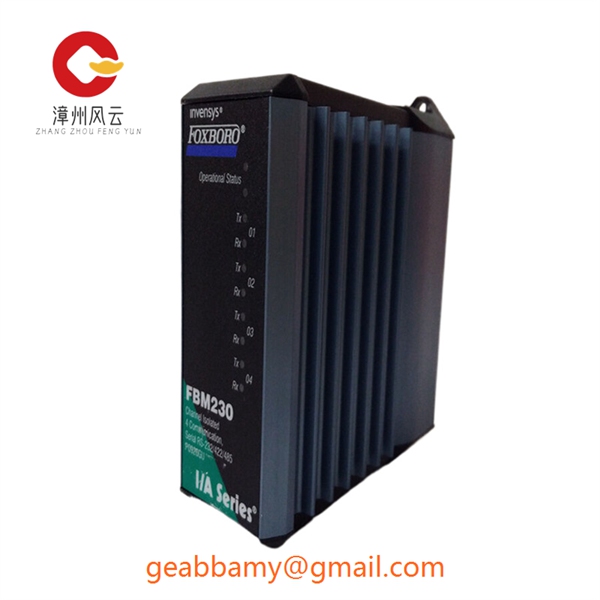

FBMSVH

The FBMSVH can provide network update solutions by integrating protocols into existing layouts and connecting them to obsolete protocols. Supported protocols include Modbus RTU, Modbus TCP, Profinet RT/IRT, DNP3.0 Ethernet, DNP3.0 Serial, IEC 60870-5-101, IEC 60870-5-103, IEC 60870-5-104, IEC 61850 Devices and PLCs. 80 different protocol combinations can be selected in the firmware. 80 different protocol combinations can be selected in the firmware and 10 different hardware platforms can be integrated depending on the network/application requirements. The Protocol Gateway series is equipped with hardware platforms and software to manage conversions between protocols. They are designed to withstand environments with a temperature range of -40°C to +85°C and humidity up to 95%. They comply with industrial EMC requirements/IEC 61850 Chapter 3. Connector types are SFP, Ethernet, TB5 or DB9 serial. DIN-Rail and Rackmount configurations are standard, and Wall Mount is optional for DIN-Rail models.

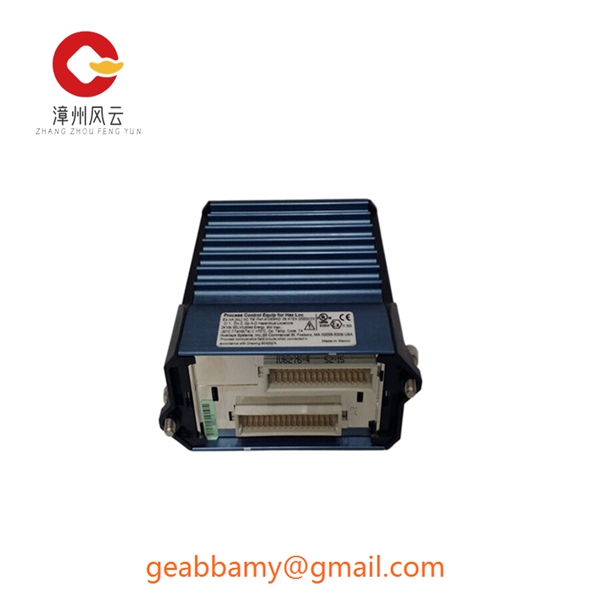

The FBMSVH features a 10.4-inch colour TFT display, graphical support for processing cycles and simulations, a USB interface built into the enclosure for simple program handling and transfer, intuitive help screens and remote diagnostics. This space-saving and cost-effective retrofit kit is pre-configured to meet the needs of most current applications on the market, including control-only retrofits that maintain and integrate the machine’s existing motors and drives.The ETT-VGA-0045 receives signals from switches or transmitters, determines the presence of abnormal process conditions, and delivers outputs to shut down isolation valves, shut down transfer pumps, or open diverter valves. The system operates independently of the plant’s process control system and is capable of communicating with the control system via hardwire, Modbus, Ethernet or wireless communications.