Product code: N/A

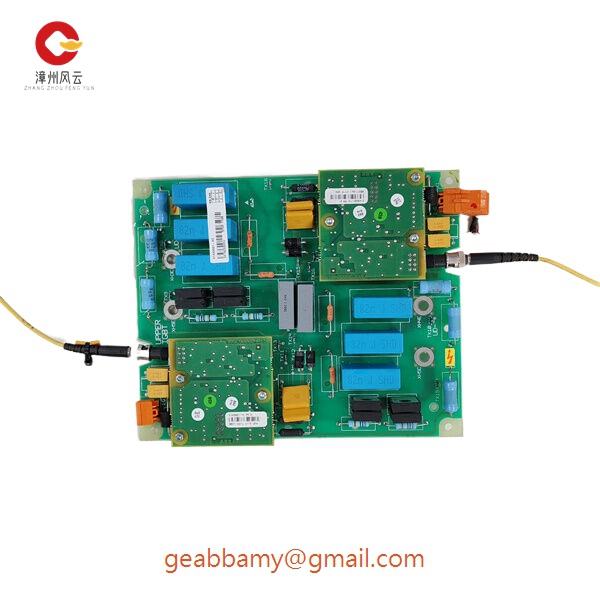

PCD235C101 3BHE057901R0101 Process Analyzer Controller

📣Model Number: PCD235C101 3BHE057901R0101

🌍Country of origin: USA France Germany Estonia Norway UK

⌚Delivery date: in stock

🛠After-sales service: brand new with one year warranty

⚙️ Product Category: Module/Controller/Server/Motor/Touch Screen

🕰Warranty: 12 months/365 days

📦Product Packaging: seller provides complete and safe protection packaging

🚚 Freight: according to the local freight forwarder, the freight should be subject to different areas.

🆓Whether tariffs are included: no taxes are included

☎️ Please contact me: 15359029662 Ms. Amy Sun

📎Chinese official website: www.dcsplcabb.com

📩Email: geabbamy@gmail.com

💬Whatsapp: +86 15359029662

Detailed content

PCD235C101 3BHE057901R0101

PCD235C101 3BHE057901R010 With this clear, concise view of loop performance, plant personnel can focus on the most important improvements. The new Loop Performance Snapshot adds a simple graphical representation of the powerful loop analysis calculations in ExperTune PlantTriage™ software.PlantTriage™ uses data from existing DCS or PLC systems to automatically monitor plant operations 24/7. After processing high-speed data from the control system, PlantTriage™ evaluates the performance of each control loop and prioritizes plant problems based on economic importance. The sensor’s easy-to-read three-inch dial provides local temperature indication over the 0-250°F and 0-500°F dial ranges, is sealed in accordance with ASME B40.3, and has field adjustable calibration. The dial has NIST-traceable calibration and is accurate to 1% of reading. The integrated RTD and thermocouple probe mounts in a 0.25-inch or 0.38-inch thermocouple bushing hole, provides up to 0.04% reading accuracy, and features sealed high-temperature wires.

PCD235C101 3BHE057901R0101 Streamlines the performance improvement process. The Loop Performance Snapshot provides all critical loop evaluations in an easy-to-understand graphical format. With this information, engineers and technicians can spend less time investigating and more time improving the plant.” The Loop Performance Snapshot includes graphical displays of the most critical loop assessment information, including oscillation detection, Key Performance Indicator (KPI) comparisons, linear and valve lag assessments, variability, uptime, dynamic process modeling, and more. Red/yellow/green codes draw the user’s attention directly to the problem area. Modules include a rugged thermowell probe assembly containing a Moore Industries RTD or thermocouple sensor and a large analog display. Both the sensor and display are NIST traceable and can be quickly calibrated in the field. No power supply is required to drive the local analog readout; the thermocouple or RTD can be read from a standard transmitter, signal conditioner, or analog input device.