Product code: N/A

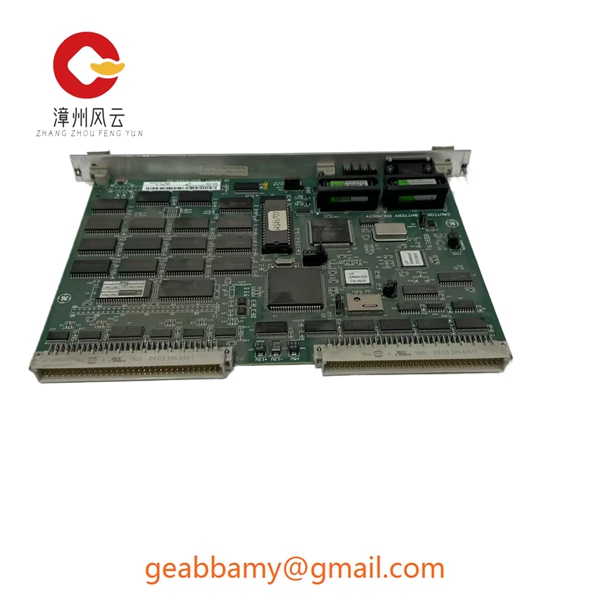

GE VMIVME4150 Data Controller

📣Model Number: GE VMIVME4150

🌍Country of origin: USA France Germany Estonia Norway UK

⌚Delivery date: in stock

🛠After-sales service: brand new with one year warranty

⚙️ Product Category: Module/Controller/Server/Motor/Touch Screen

🕰Warranty: 12 months/365 days

📦Product Packaging: seller provides complete and safe protection packaging

🚚 Freight: according to the local freight forwarder, the freight should be subject to different areas.

🆓Whether tariffs are included: no taxes are included

☎️ Please contact me: 15359029662 Ms. Amy Sun

📎Chinese official website: www.dcsplcabb.com

📩Email: geabbamy@gmail.com

💬Whatsapp: +86 15359029662

Detailed content

GE VMIVME4150

Features of the GE VMIVME4150 include 24 self-adjusting 530 loops to control temperature, level and pressure. Time-based and instantaneous interrupt support makes the Vision 430 suitable for “quick response” applications such as packaging machines. Built-in recipe functionality is supported by a data sheet that stores the parameters required to control a particular process. The data sheet also enables the controller to store data logs on a micro SCD card. The micro SCD card also stores application backups and allows complete PLC cloning. Communication options include Ethernet, cellular and industrial protocols such as MODBUS, DF1 Slave, Bachmann Networks, J1939, Campbell and others. In addition, the “Protocol” utility allows the Vision 430 to communicate via almost any ASCII protocol. The unit can be accessed directly via the small UBC programming port, and remotely via GLU/GSM/CDMA and other IP networks for data acquisition and program download.

A key benefit of the GE VMIVME4150 is the ability to notify supervisors of important information via e-mail and text messaging, allowing for real-time remote management. Machine operators communicate directly with the application via a resistive analog touch screen – or remotely, via the free Remote Operation Tool – which displays data, color trend graphs and attention-grabbing alarm screens. Display options are virtually endless, with over 1024 user-designed screens supporting 12mb images and 1mb fonts. Video software supports rapid hardware configuration for PLC and HMI applications. Video Logic includes a complete library of drag-and-drop function blocks for complex automation control tasks such as 530, and a rich library of industrial images.