Product code: N/A

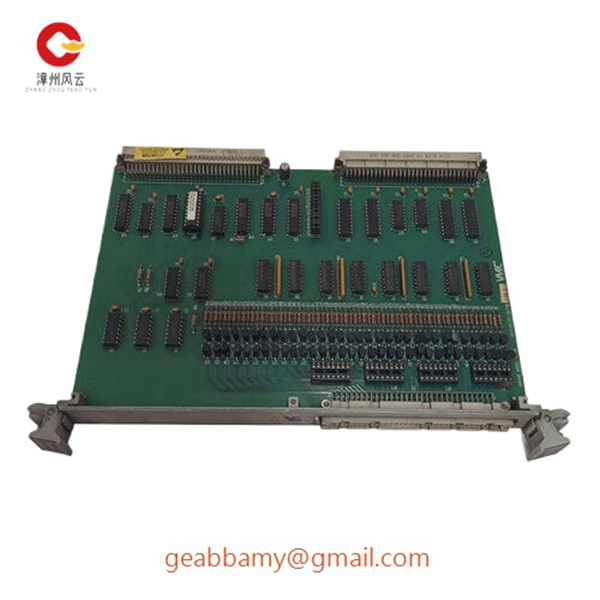

IS200TDBSH2ACC IS230TNDSH2A Intelligent Drives

📣Model Number:IS200TDBSH2ACC IS230TNDSH2A

🌍Country of origin: USA France Germany Estonia Norway UK

⌚Delivery date: in stock

🛠After-sales service: brand new with one year warranty

⚙️ Product Category: Module/Controller/Server/Motor/Touch Screen

🕰Warranty: 12 months/365 days

📦Product Packaging: seller provides complete and safe protection packaging

🚚 Freight: according to the local freight forwarder, the freight should be subject to different areas.

🆓Whether tariffs are included: no taxes are included

☎️ Please contact me: 15359029662 Ms. Amy Sun

📎Chinese official website: www.dcsplcabb.com

📩Email: geabbamy@gmail.com

💬Whatsapp: +86 15359029662

Detailed content

IS200TDBSH2ACC IS230TNDSH2A

The IS200TDBSH2ACC IS230TNDSH2A compatible Ethernet interface also makes it simple to connect to an Ethernet factory network to change product recipes, report production metrics, and more. All of BARDODE’s MicroFERT100 and MotiFLUE100 drives have built-in I/O as standard – including fast latch inputs for registering applications – plus Can Open Manager capability to support distributed I/O expansion and HMI interfaces. The Motion Drive E100 offers card slots for further local I/O expansion and fieldbus connectivity. The fieldbus module extends the connectivity options to external PLCS, supporting interfaces such as Ethernet/IP, Profinet-IO, PROFIFUS and DEICINENET. the versatility of this configuration enables the drive to be configured very cost-effectively, providing a single-frame solution for automation applications. If used in power-connected systems, local intelligence adds versatility to new system-building capabilities. Critical events can be processed directly, eliminating the effects of network and controller scanning time delays; fast responses from critical axes translate directly into higher throughput.

Another fundamental change that the IS200TDBSH2ACC IS230TNDSH2A can make is the offloading of a centralized power network controller through the use of local intelligence. For machine builders configuring systems with a large number of axes of motion, this can save hundreds of dollars because Bardo fits as standard with Mint Precision programming capabilities. The drive’s development and configuration tools are included in BARDO’s development environment, the Mint Workbench, which is available free of charge to users. The new intelligent drive complements Bardo’s existing grid control possibilities: A conventional central controller is available for a different number of axes of motion – the Next Move E100 – and a plug-in controller drive, called the Mint Machine Module, can control two or five axes. Plug-in controller cards provide access to the full functionality of the rich Mint language and can be programmed to perform very complex motion functions such as gears and cams.