Product code: N/A

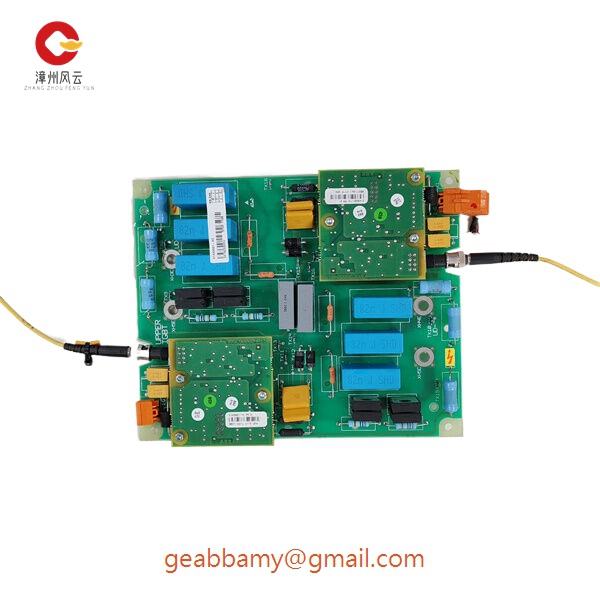

CI871AK01 3BSE092693R1 Data Function Checker

📣Model Number: CI871AK01 3BSE092693R1

🌍Country of origin: USA France Germany Estonia Norway UK

⌚Delivery date: in stock

🛠After-sales service: brand new with one year warranty

⚙️ Product Category: Module/Controller/Server/Motor/Touch Screen

🕰Warranty: 12 months/365 days

📦Product Packaging: seller provides complete and safe protection packaging

🚚 Freight: according to the local freight forwarder, the freight should be subject to different areas.

🆓Whether tariffs are included: no taxes are included

☎️ Please contact me: 15359029662 Ms. Amy Sun

📎Chinese official website: www.dcsplcabb.com

📩Email: geabbamy@gmail.com

💬Whatsapp: +86 15359029662

Detailed content

CI871AK01 3BSE092693R1

CI871AK01 3BSE092693R1 automatically generates accurate synthetic documentation that can be useful for reverse engineering, whether it is for new development based on legacy code or for maintenance and modernization. Unfortunately, code is often the only documentation available, and working on an undocumented program is always a waste of time. In addition, writing documentation manually is tiresome and error-prone. The need for a consistent format and the tediousness of the work require a tool-based automation approach. The module automatically generates a data-flow oriented view of the PLC program (from inputs to outputs) represented by formulas and flowcharts, thus abstracting the actual sequential execution of the program. This view is the perfect intermediate formalism between the specification and the code itself. It is independent of the programming style and type of PLC hardware on which the program runs. In addition, modules can be parameterized to use any type of documentation template (header blocks, symbols, …), thus ensuring consistent formatting of all documentation.

The CI871AK01 3BSE092693R1 checker improves the readability, maintainability and robustness of PLC programs through its unique functionality, which automatically verifies compliance with coding rules, naming and structuring specifications and programming standards. It replaces manual proofreading of programs, which can take a long time, thus enabling industrial users of PLCS to systematically adopt coding standards and ensure the consistency of their programs.PLC Checker is commonly used in contractual relationships, where it is a key factor in determining quality objectives. Using PLC Checker, contractors demonstrate the quality of their projects with one of the most innovative solutions on the market. Industrial users of sustainable production systems benefit from a program that is easy to read and maintain, and can use the results of PLC inspections as formal, repeatable and detailed acceptance criteria. As a result, it is easy to use for projects that require no capital expenditure or maintenance. Now extends its standard machine sequencing and motion control capabilities to include triangular and ska-type robot mechanisms, with kinematic conversion options.

_副本.jpg)