You are here:

- Home

- Product

- BENTLY NEVADA

- BENTLY 3500/42M 176449-02 Network Servers

Product code: N/A

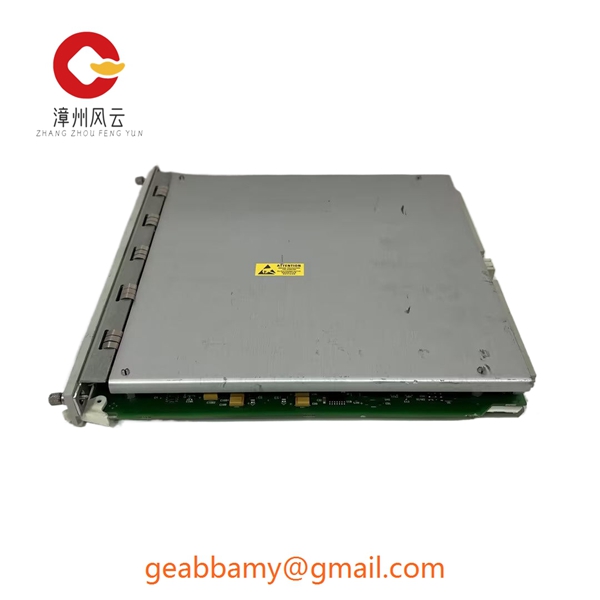

BENTLY 3500/42M 176449-02 Network Servers

📣Model Number:BENTLY 3500/42M 176449-02

🌍Country of origin: USA France Germany Estonia Norway UK

⌚Delivery date: in stock

🛠After-sales service: brand new with one year warranty

⚙️ Product Category: Module/Controller/Server/Motor/Touch Screen

🕰Warranty: 12 months/365 days

📦Product Packaging: seller provides complete and safe protection packaging

🚚 Freight: according to the local freight forwarder, the freight should be subject to different areas.

🆓Whether tariffs are included: no taxes are included

☎️ Please contact me: 15359029662 Ms. Amy Sun

📎Chinese official website: www.dcsplcabb.com

📩Email: geabbamy@gmail.com

💬Whatsapp: +86 15359029662

Detailed content

BENTLY 3500/42M 176449-02

The BENTLY 3500/42M 176449-02 offers unmatched reliability. The Inspector 101E offers all the simplicity and power of the original Inspector 101, plus it accepts encoder signals directly, eliminating the need in tracking and rejecting parts on variable speed lines.” The simplicity of using the Inspector 101 sensor fundamentally changes the way sensor users inspect a part or parts by eliminating the complex wiring, mounting, ladder logic programming, and precise part handling required to use multiple photoelectric sensors,” said Brian Phillips, vice president of Kognex, the expert on sensors.” By receiving encoder signals directly, the 101E Inspector eliminates the cost and complexity of PLCs tracking and rejecting parts on variable speed lines.

BENTLY 3500/42M 176449-02 Unlike shift registers for PLCs that require programming, the Inspector’s shift registers are automatic, allowing it to accurately track up to 4,000 parts between inspection and rejection points.” Acquiring and processing more than 500 images per second, the inspector is able to detect and inspect parts on the fastest production lines. If inspection is not required, the inspector can be used to detect and track parts or nets for improved process control. The step-by-step setup of the Inspector makes it easy for anyone on the factory floor to deploy. Inspector 101E is now available. The Inspector 101E eliminates the cost and complexity of PLC’s for part tracking and rejects on the changeover line. Unlike shift registers for PLCs that require programming, the Inspector’s shift registers are automated, making it possible to accurately track up to 4,000 parts between inspection and rejection points.

_副本.jpg)